Kerax is one of Europe’s leading industrial wax manufacturers, supplying high-performance waxes for paper & packaging, textile coatings, general industrial processes, rubber and plastics, hot melt adhesives, defeathering, and surface treatments. Kerax formulations are designed to deliver stability, durability, lubricity, and temperature resistance across demanding manufacturing environments.

General Industrial Wax FAQs

1. What types of industrial waxes does Kerax supply?

Kerax supplies a comprehensive portfolio of industrial waxes including paraffin wax, microcrystalline wax, synthetic waxes, polyethylene waxes, hybrid blends, and custom-engineered systems. These waxes serve applications in packaging, coatings, adhesives, plastics, agriculture, and manufacturing.

2. What makes Kerax industrial waxes different?

Kerax combines decades of formulation expertise with refined processing to create waxes that are consistent in melting point, hardness, viscosity, and colour, ensuring reliable repeat performance for industrial production lines.

3. Can Kerax develop bespoke industrial wax blends?

Yes. Kerax offers toll manufacturing and custom formulation, working closely with OEMs and industrial partners to create wax solutions for specific application needs, performance targets, and regulatory standards.

4. Are Kerax industrial waxes compliant with safety and environmental regulations?

Kerax industrial waxes adhere to REACH, EU food-contact regulations (where applicable), and industry-specific compliance standards. Full technical data sheets (TDS) and safety data sheets (SDS) are available.

Paper & Packaging Wax FAQs

Kerax offers high-quality waxes for paper coating, lamination, packaging protection, food-contact applications (where approved), and moisture barriers.

1. What is paper & packaging wax used for?

Kerax waxes provide moisture resistance, grease resistance, surface protection, and enhanced barrier properties for paper and board materials used in food wraps, cartons, and corrugated packaging.

2. Are Kerax packaging waxes suitable for food applications?

Certain Kerax waxes meet EU food-contact compliance and are suitable for direct and indirect food packaging. Always confirm compliance in the TDS.

3. Which wax grades are commonly used in paper coating?

Typical grades include paraffin wax, microcrystalline wax, and speciality blends, chosen for their film-forming properties and controlled melt points.

Textile Coatings Wax FAQs

Kerax waxes improve the feel, finish, performance, and durability of textile products.

1. Why are waxes used in textile coating?

Wax coatings enhance lubricity, water repellence, softness, and abrasion resistance, improving both the handling and longevity of textiles.

2. Which textiles benefit from wax coatings?

Common applications include technical textiles, industrial fabrics, outdoor clothing, leather finishing, and shoelace coatings.

3. Are Kerax textile waxes customisable?

Yes. Kerax can tailor melt point, hardness, and viscosity to suit specific coating machines and product requirements.

General Purpose & Industrial Wax FAQs

These waxes serve versatile roles across manufacturing, mechanical processing, and surface protection.

1. What are general-purpose industrial waxes used for?

They are used in wood treatment, lubrication, mould release, waterproofing, casting, polishes, and corrosion protection.

2. What types of wax fall into this category?

A variety of waxes including paraffin, microcrystalline, hybrid synthetic waxes, and polyethylene waxes.

3. Are these waxes suitable for high-temperature applications?

Yes — Kerax designs waxes with controlled melting points to ensure stability in varied industrial environments.

Surface Treatment Wax FAQs

Kerax surface treatment waxes deliver gloss, protection, and improved processability for surfaces such as wood, metal, and composites.

1. What is surface treatment wax used for?

It provides protection, shine, lubrication, and moisture resistance for treated surfaces.

2. Which industries use surface treatment waxes?

Applications include wood finishing, metal protection, casting, automotive polishing, and household goods.

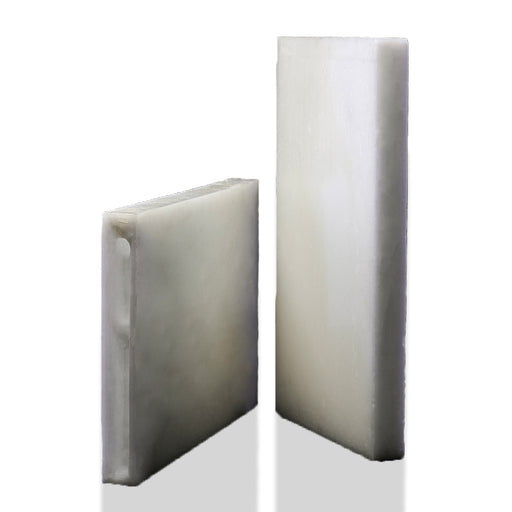

3. Are surface treatment waxes available in different forms?

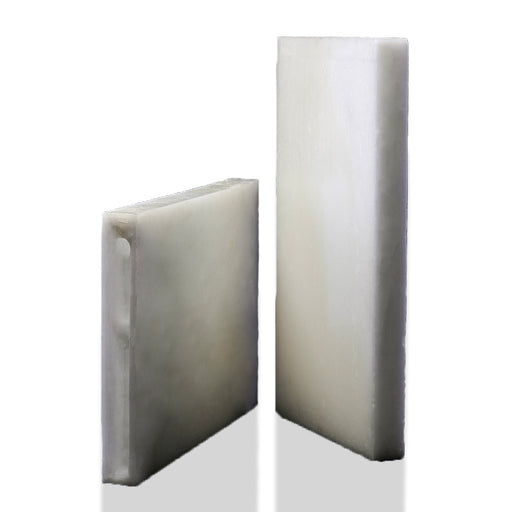

Yes — Kerax supplies waxes in flakes, pastilles, blocks, and emulsions depending on production requirements.

Defeathering Wax FAQs

Kerax is one of the UK’s leading suppliers of defeathering wax for poultry processing.

1. What is defeathering wax?

Defeathering wax is a specialised wax used in poultry processing to remove pinfeathers and fine down after scalding.

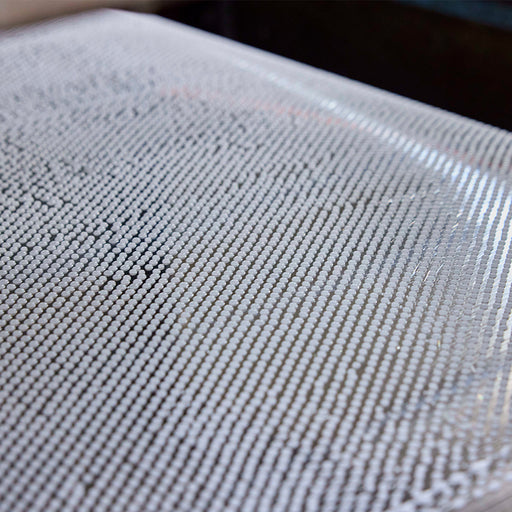

2. What makes Kerax defeathering wax effective?

Kerax formulations offer optimal elasticity and tack, allowing feathers to bond effectively and release cleanly during the waxing process.

3. Is defeathering wax reusable?

Yes — Kerax wax can be melted, filtered, and reused, offering excellent cost efficiency.

Rubber & Plastic Processing Wax FAQs

Kerax waxes support polymer processing, extrusion, moulding, and compounding.

1. What does wax do in rubber and plastic processing?

Wax functions as a processing aid, lubricant, slip agent, and dispersion enhancer, improving flow and reducing viscosity.

2. Which industries use these waxes?

Applications include tyre manufacturing, EVA foam, PVC compounding, injection moulding, and extrusion.

3. Are Kerax polymer processing waxes compatible with additives?

Yes — they integrate with stabilisers, colourants, resins, and fillers for balanced performance.

Hot Melt Adhesive Wax FAQs

Kerax supplies waxes that enhance bond strength, flexibility, and open time in hot melt adhesives.

1. Why is wax used in hot melt adhesives?

Waxes help control open time, viscosity, hardness, and improve overall adhesive strength and consistency.

2. What types of adhesives benefit from wax additives?

Applications include packaging adhesives, bookbinding, hygiene products, and industrial assembly.

3. Can Kerax provide custom adhesive wax blends?

Yes — Kerax develops tailored wax systems optimised for viscosity, melt point, and performance stability.

Toll Manufacturing FAQs

Kerax offers toll manufacturing services for industrial clients requiring bespoke wax production.

1. What is toll manufacturing?

Toll manufacturing means Kerax produces wax blends or finished products to your formula or specification using our manufacturing facilities.

2. What are the advantages of toll manufacturing with Kerax?

Kerax provides custom formulation, quality control, scalable production, bulk handling, and full regulatory compliance.

3. What industries use Kerax toll manufacturing services?

Industries include packaging, adhesives, textiles, plastics, cosmetics, and specialised industrial coatings.