Defeathering Waxes

Kerax Defeathering Waxes

In poultry processing, efficiency and precision are crucial. Kerax introduces Defeathering Waxes in pastille and slab forms, crafted with precision for superior feather removal. These specialised waxes offer ease of application and consistent results, revolutionising poultry processing. Whether on a small farm or large facility, choose Kerax for optimal efficiency.

Advanced Formulation for Superior Performance:

At Kerax, innovation drives everything we do. Our Defeathering Waxes are formulated using advanced technologies and the finest raw materials to deliver superior performance and reliability. Whether in pastille or slab form, each wax is engineered with precision to ensure optimal feather removal and minimal damage to poultry skin. With Kerax Defeathering Waxes, you can trust that every application will result in consistent and uniform results, maximising efficiency and throughput in your processing operations.

Gentle and Effective Feather Removal:

The key to successful poultry processing lies in achieving gentle yet effective feather removal. Kerax Defeathering Waxes are specially formulated to adhere to feathers while softening the keratinous sheath, making them easier to remove without causing damage to the underlying skin. Whether used in immersion tanks, rotary drum pluckers, or other defeathering equipment, our waxes ensure efficient and thorough feather removal, resulting in high-quality poultry products with minimal downtime and waste.

Reduced Processing Time and Costs:

Time is money in poultry processing, and Kerax Defeathering Waxes are designed to streamline operations and reduce processing time and costs. By facilitating faster and more efficient feather removal, our waxes help poultry processors increase throughput, optimise resource utilisation, and minimize labor costs. With Kerax, you can achieve higher productivity and profitability in your processing operations without compromising on the quality of your end products.

Consistent Performance in Various Conditions:

Whether processing chickens, turkeys, ducks, or other poultry species, Kerax Defeathering Waxes offer consistent performance in a variety of conditions. Our waxes maintain their effectiveness across a wide range of temperatures and humidity levels, ensuring reliable feather removal even in challenging environments. With Kerax, you can trust that every batch of poultry will undergo consistent and uniform defeathering, regardless of external factors.

Ease of Application and Handling:

Kerax Defeathering Waxes are designed for ease of application and handling, whether in pastille or slab form. Their convenient packaging and user-friendly formats allow for easy storage, measurement, and handling in poultry processing facilities. Whether applied manually or integrated into automated defeathering systems, our waxes offer seamless integration into your processing operations, minimising downtime and maximising efficiency.

Solutions for Specific Needs:

Kerax understands that every poultry processing operation is unique, with specific requirements and challenges. That’s why we offer customisable solutions to meet your individual needs. Whether you require waxes with specific melting points, hardness levels, or additives, we can tailor our formulations to address your specific requirements. With Kerax, you can achieve optimal results and maximise efficiency in your poultry processing operations.

Choose Kerax for Excellence in Poultry Processing:

In the competitive world of poultry processing, Kerax stands as your trusted partner for excellence, innovation, and reliability. With our precision-engineered Defeathering Waxes, you can optimise your processing operations, achieve superior feather removal, and enhance the quality of your end products. Choose Kerax and experience the difference in poultry processing solutions that empower efficiency and excellence for a brighter future.

Wax Form

Showing all 2 results

-

£80.00

PRODUCT DETAILS Kerawax 422 Paraffin Candle Wax 56/58 Kerax Candle Paraffin Wax blends are manufactured from the highest quality raw materials in order to allow…

From £80.00 inc. VAT

Buy Now -

£0.00

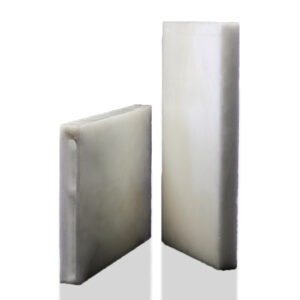

Specialized defeathering wax for poultry processing Consistent performance across varied temperatures Flexible and durable for repeated use Supplied in 1,000kg boxes of convenient slabs Ideal…

THE UK’S LEADING WAX MANUFACTURER

With over 60 years of experience, we have been leading the way in wax manufacturing and blending since 1962. From candle wax to protective surface waxes, we have everything you need when it comes to waxes and wax blends.

We don’t just make wax – our extensive range also includes petroleum jellies for pharmaceutical, cosmetic, industrial, and commercial use.

Our team of dedicated chemists are always seeking new and innovative ways to use wax in commercially viable applications.