UK’s leading construction equipment manufacturer uses novel wax emulsion to eliminate VOCs and improve lubrication.

The Client

The client is the UK’s largest manufacturer of construction equipment, employing over 15,000 people globally and supplying customers across the world.

The Problem

The customer was served a prohibition notice by the UK government to remove Volatile Organic Compounds (VOCs) from their production processes due to the detrimental impact on workers’ health. At the same time, new regulations in their key markets meant that the customer was losing opportunities as they were unable to continue supplying their clients with products that contained VOCs. This meant that the customer was unable to fulfill their service pack requirements in certain geographies and was losing potential income. The solution needed to be useable in their four production sites and by their customers out in the field.

The customer had several challenges and opportunities to address by working with Kerax to develop a new lubricant that fit the changing regulatory landscape.

The required outcomes of the solution were defined as:

- Remove VOCs from the product

- Improve upon existing product performance, measured by co-efficient of friction

- Easy to apply across their factories and by customers globally

- Meet or exceed existing product price

The customer tendered the opportunity to develop a new lubricant that addressed their key requirements.

The solution

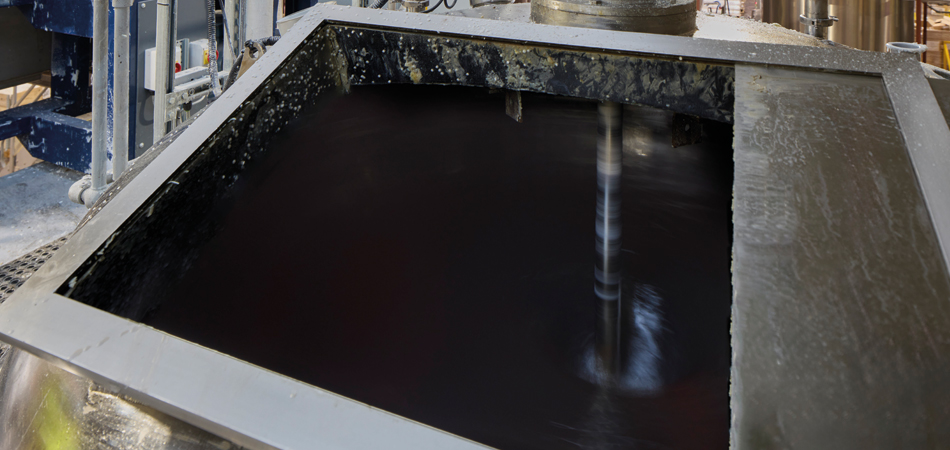

Kerax was approached to enter the tender due to a reputation of deep sector knowledge of waxes and wax emulsions. It was determined during project scoping that a wax emulsion was the most suitable product, with Kerax having the capabilities to manufacture this at our factory in Chorley, UK.

During project scoping, Kerax engaged with the client’s purchasing and factory teams to discover the specific issues that the company faced. Analysis was performed on the existing product to determine the areas of performance to match and improve. Kerax reviewed existing raw materials that could be blended to provide similar benefits, providing the customer with initial samples. Following this, Kerax entered into an iterative development project over four years to further tailor the formulation and wax emulsion for the customer.

During the course of the project, the customer tested 40 off-the-shelf solutions and 160 wax emulsion formulations. The solution that was selected successfully completed 70,000 hours of endurance tests across the customer’s global facilities and at selected dealers.

The results

The end result was an improved wax emulsion that delivered:

- 99% reduction of VOCs

- 17% better co-efficient of friction than the existing product

- Compliance with global regulations to deliver increased sales opportunities

- Exceeded customer price expectations

Kerax partners closely with manufacturers to deliver products that go above and beyond their expectations. We achieve this through leveraging our deep sector knowledge, collaborative and flexible way of working alongside significant production capabilities. Kerax, Making Wax Work.

Contact Kerax now to discuss solutions.

enquiries@kerax.co.uk

+44 (0) 1257 237350

Kerax Limited

Cowling Road

Chorley

United Kingdom

PR6 9DR